Polakril Sheet

In parallel with the recent developments in the construction sector, there has been a noticeable tendency towards acrylic applications in kitchen and bathroom countertop designs.

Our company, which closely follows the developments in line with this orientation, has accelerated the production of solid sheet with Polakril brand.

By increasing its quality with the latest investments, it has become a brand preferred by architects in our country.

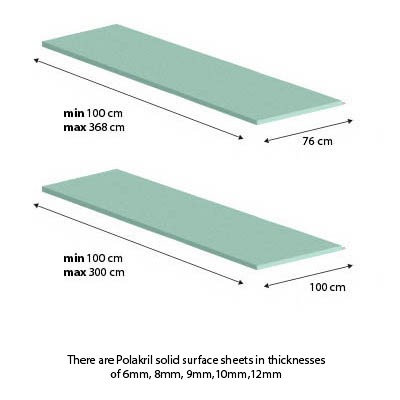

Standard sheet sizes:

- 76cm * 368cm

- 100cm * 300 cm

- 107 cm * 317 cm

In these sizes, we have 6mm, 8mm, 9mm, 10mm, 12mm thickness plates.

WHY POLAKRİL ?

Polakril provides the following advantages to its customers compared to its competitors.

- Since it can produce the desired length on demand, it reduces the waste in plate sizes to zero.

- It offers a wide range of thickness options ranging from 6mm to 24mm.

- It responds to orders in a short time by using the advantages of being a manufacturer.

- Thanks to the technological investments we have made, any desired colour can be worked in line with customer demand.

- Since our products are 100% acrylic based, they can be subjected to all kinds of thermo formic processing.

- With its dirt and bacteria-free feature, it is a compulsory surface material for counter and wall coverings in intensive care units in hospitals.

- Polakril, which is produced from 100% acrylic resin, is a sought-after design product with its mono-block, dirt-repellent feature and unlimited colour options in all kinds of kitchen and bathroom countertops, marine vehicles such as yachts, commercial centres, airports, workplace stands.

- Polakrill acrylic sheet is renewable because it is a decorative surface material, has a solid surface and every point has the same feature.

- Acrylic Polakril sheets are not similar to natural stones. There is no coating material on the surface.

|

POLAKRİL SPECIFICATIONS |

|||

|

STANDARDS |

UNIT |

VALUES |

|

|

DENSITY |

DIN53 455 |

|

1.78 |

|

TENSILE RESISTANCE |

DIN53455 |

N/mm² |

25 |

|

BENDING STRENGTH |

DIN53452 |

N/mm² |

35 |

| IMPACT STRENGTH |

DIN50351 |

Kj/m2 |

4,8 |

|

HARDNESS,BRİNELL NUMBER |

DIN50 351 |

|

208 |

|

HARDNESS,BARCOL NUMBER |

ASTM D-256 |

|

57 |

|

FLAME RESISTANCE |

DIN53 438 |

|

CLASS 1 |

|

HEAT RESISTANCE |

DIN68 390 |

|

AT 100 DEGREE CELCIUS NO CHANGE |

|

CIGARETTE EXTINGUISHING TEST |

DIN 53799 |

EYE CONTROL |

NO TRACE ON THE SURFACE

|

|

HOT POT RESISTANCE TEST |

DIN53799, 4,9 |

AT 180-190 DEGREE CELCIUS, WAITED 20 MİNS |

NO CRACK ON THE SURFACE |

|

WATER ABSORPTION |

DIN 53799 , 4,10 |

|

%0,6 |

|

RESISTANCE TO MICROORGANISM FORMATION |

RODAC AND SWAB SYSTEMS |

|

NO FORMATION |

|

STAIN RETENTION TEST

|

DIN 53799 4,14,5,1 |

EXPERIMENT 4,14,5,1, according to methods A,B,C, different substances were tested in four different groups; acetone, ethylalcohol, trichloroethylene, ammonia, acetic acid, cola, vinegar, soap, saturated salt solution, cream, lemon, toothpaste, oil, etc. |

NO STAIN SEEN ON THE SURFACE |